Our Courses

We always work with experts, all the workers work with expertise,

there is no conflict between them.

Lean Process and Six Sigma (5 Days)

Module One: Getting Started

Workshop Objectives

Pre-Assignment Review

Module Two: Understanding Lean

About Six Sigma

About Lean

History behind Lean

Toyota Production Systems

The Toyota Precepts

Module Three: Liker’s Toyota Way

Philosophy

Process

People and Partners

Problem Solving

Module Four: The TPS House 15

The Goals of TPS

The First Pillar: Just In Time (JIT)

The Second Pillar: Jidoka (Error-Free Production)

Kaizen (Continuous Improvement)

The Foundation of the House

Module Five: The Five Principles of Lean Business

Value

Value Stream

Flow

Pull

Seek Perfection

Module Six: The First Improvement Concept (Value)

Basic Characteristics

Satisfiers

Delighters

Applying the Kano Model

Module Seven: The Second Improvement Concept (Waste)

Muda

Mura

Muri

The New Wastes

Module Eight: The Third Improvement Concept (Variation)

Common Cause

Special Cause

Tampering

Structural

Module Nine: The Fourth Improvement Concept (Complexity)

What is Complexity?

What Causes Complexity?

How to Simplify?

Module Ten: The Fifth Improvement Concept (Continuous

Improvement)

The PDSA Cycle (Plan, Do, Study, Act)

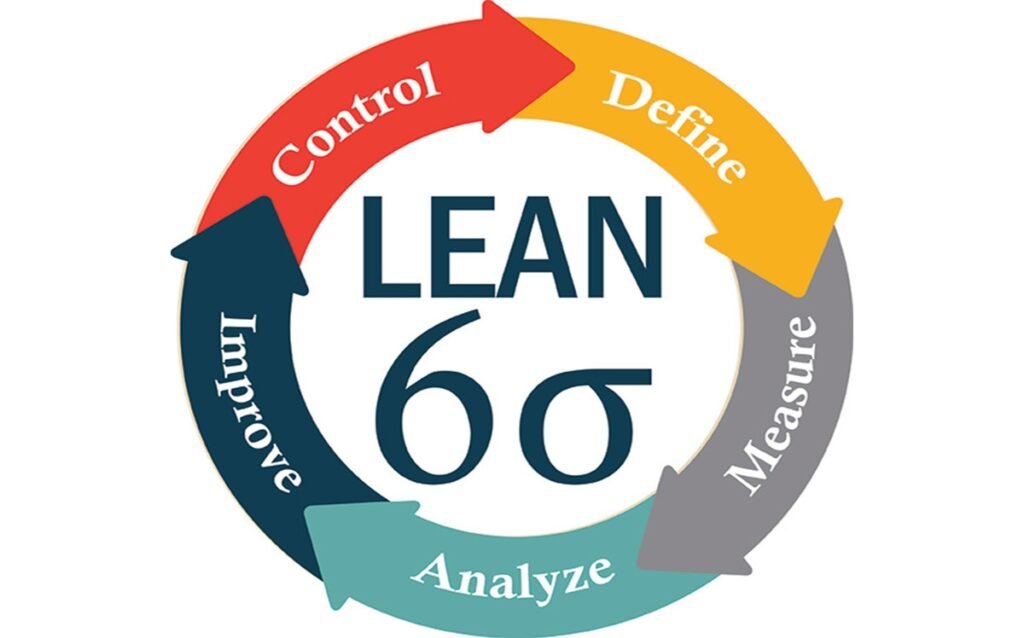

The DMAIC Method

Module Eleven: The Improvement Toolkit

Gemba

Genchi Genbutsu

Womack’s Principle

Kaizen

A Roadmap for Implementation

Module Twelve: Wrapping Up

Words from the Wise

USD:400.00 Per Participant (Ask for the Discount) MINIMUM 10 IN ONE GROUP.

(With Lunch and 2 Coffee Breaks), Printed Course Material and Certificate.

Duration: TWO Days (5 Hour's Per day)

Register